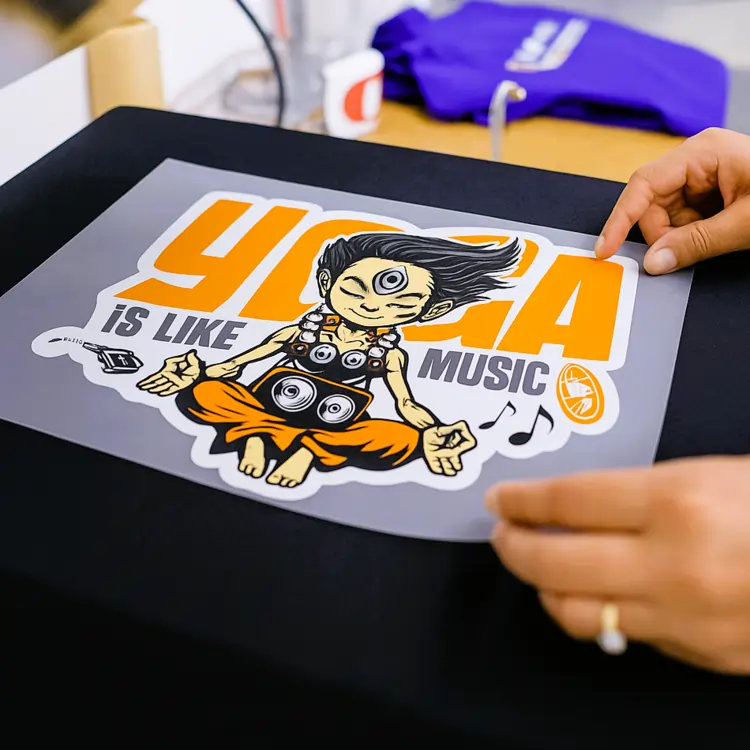

Sticker Design Tips for Perfect Custom Prints

Creating an eye-catching sticker starts with a great design. Whether it’s for branding, packaging or personal use, here are some useful sticker design tips to help your prints stand out:

1.Keep It Simple and Clear

A clean design with minimal elements is easier to read and recognize. Avoid overcrowding your sticker with too much text or detail.

2.Use Bold Colors and Contrast

Bright, high-contrast colors make your design more noticeable from a distance. Make sure your text and background have enough contrast for readability.

3.Choose the Right Shape and Size

Match your sticker’s shape to your design. Round, square or custom die-cut shapes can help emphasize your brand’s personality.

4.Include Your Branding

Don’t forget to add your logo, brand name or website. Stickers are a great way to boost brand visibility and recall.

5.Mind the Bleed Area

Leave extra space around the edges of your design to ensure no important details are cut off during trimming.

6.Pick the Right Finish

Decide between matte, glossy or transparent finishes based on where and how your stickers will be used. Glossy adds shine, matte gives a premium feel and transparent looks sleek.

7.Test Before Printing in Bulk

Always print a sample to check colors, size, and clarity before ordering large quantities.

Why Print Your Stickers with Quapri

At Quapri, we make custom sticker printing simple, affordable and high-quality. Whether you need kiss cut or die cut stickers, our advanced printing technology ensures sharp colors, precise cuts and long-lasting durability.

Why Choose Quapri?

- High-quality printing on vinyl and paper materials.

- Multiple finishes — matte, gloss, and transparent.

- Fully customizable shapes and sizes.

- Affordable pricing for bulk and small orders.

- Fast turnaround and delivery across India.

Whether you’re a small business, event organizer or creative entrepreneur, Quapri helps you bring your designs to life with professional custom sticker printing that stands out.

Explore more about custom sticker printing and creative design options here.

Perfect Bind Notebook

₹125.00

Perfect Bind Notebook

₹125.00

Personalized Coffee Mugs

₹235.00

Personalized Coffee Mugs

₹235.00

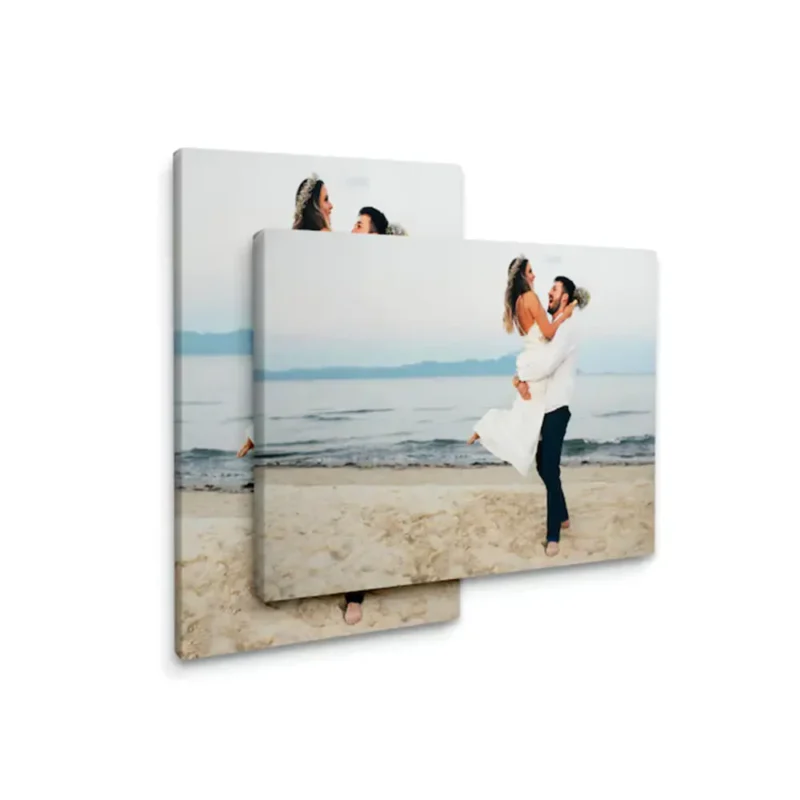

Custom Canvas Prints

₹715.00

Custom Canvas Prints

₹715.00

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit