-

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

-

Personalized Coffee Mugs

₹235.00

Personalized Coffee Mugs

₹235.00

-

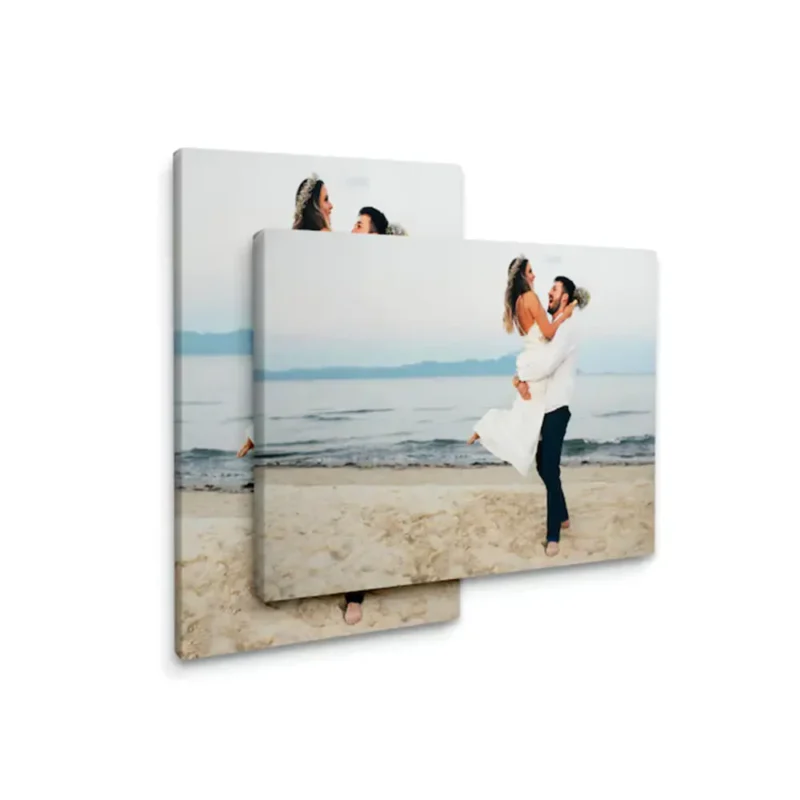

Custom Canvas Prints

₹715.00

Custom Canvas Prints

₹715.00

-

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Coffee Mugs

₹235.00

Personalized Coffee Mugs

₹235.00

Custom Canvas Prints

₹715.00

Custom Canvas Prints

₹715.00

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

Stainless Steel Bottles

₹450.00

Stainless Steel Bottles

₹450.00

5-in-1 Gift Set

₹2,500.00

5-in-1 Gift Set

₹2,500.00

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Eco-Friendly Business Card

From ₹4.60 per unit

Eco-Friendly Business Card

From ₹4.60 per unit

Circle Visiting Cards

From ₹2.25 per unit

Circle Visiting Cards

From ₹2.25 per unit

Metallic Business Cards

From ₹5.80 per unit

Metallic Business Cards

From ₹5.80 per unit

Matte Laminated Business Cards

From ₹3.20 per unit

Matte Laminated Business Cards

From ₹3.20 per unit

Glossy Laminated Visiting Cards

From ₹2.35 per unit

Glossy Laminated Visiting Cards

From ₹2.35 per unit

Personalized Bamboo Pencils

From ₹45.00 per unit

Personalized Bamboo Pencils

From ₹45.00 per unit

Premium Black Ballpoint Pen

₹410.00

Premium Black Ballpoint Pen

₹410.00

Metallic Ballpoint Pens

₹180.00

Metallic Ballpoint Pens

₹180.00

Stainless Steel Bottles

₹450.00

Stainless Steel Bottles

₹450.00

Temperature Water Bottles

₹900.00

Temperature Water Bottles

₹900.00

Personalized Bamboo Water Bottles

₹1,150.00

Personalized Bamboo Water Bottles

₹1,150.00

Thermos Water Bottles

Thermos Water Bottles

Awards and Certificates

Awards and Certificates Lanyards

From ₹25.20 per unit

Lanyards

From ₹25.20 per unit

Lanyard with Side Lever Hook

From ₹48.00 per unit

Lanyard with Side Lever Hook

From ₹48.00 per unit

Lanyard with Twisted Hook

From ₹46.25 per unit

Lanyard with Twisted Hook

From ₹46.25 per unit

When it comes to printing, choosing the right method can make a big difference in quality, cost and durability. Two popular printing methods used today are Screen Printing vs UV Printing. Many businesses, designers and marketers often get confused when deciding between these two. This detailed guide on screen printing vs UV printing will help you understand how both methods work, their benefits, drawbacks and which one suits your needs best. By the end of this blog, you will be able to choose the right printing solution with confidence.

Screen printing is one of the oldest and most widely used printing methods. It involves pushing ink through a mesh screen onto a surface. Each color needs a separate screen, which makes the process more detailed but very effective for bulk printing.

This method is commonly used for t-shirts, bags, caps, posters and packaging materials.

UV printing is a modern printing method that uses ultraviolet light to dry ink instantly. The ink cures as soon as it touches the surface, giving sharp and vibrant results.

UV printing works well on paper, plastic, glass, metal, wood, acrylic and more.

Screen printing produces bold and solid colors. The ink is absorbed into the material, especially on fabric. This makes the print very durable and long-lasting. However, it is not ideal for designs with fine details or color gradients.

UV printing delivers high-resolution prints with fine details. It is perfect for logos, images and designs that need clarity. The ink stays on the surface, giving a clean and polished look.

In simple terms:

One of the biggest differences between screen printing and UV printing is the type of materials they can be used on.

Screen printing works best on soft and flat surfaces. It is commonly used on:

Because the ink is pushed through a screen, this method is mainly suitable for materials that can absorb ink easily. That’s why screen printing is often chosen for apparel and basic packaging.

On the other hand, UV printing is much more flexible when it comes to materials. It can be used on:

Since UV ink dries instantly with UV light, it sticks well to many different surfaces. This makes UV printing a great option when you want to print on hard or non-traditional materials. In simple words, screen printing is best for soft and flat items, while UV printing gives you more freedom to print on a wide range of materials.

Both methods provide durable results when used correctly.

Your budget and order size play a major role in choosing the right method.

If speed is important, UV printing is usually the better option.

UV printing is considered more environmentally friendly.

| FEATURE | SCREEN PRINTING | UV PRINTING |

|---|---|---|

| Best for | Bulk orders | Small & custom orders |

| Print detail | Medium | High |

| Material range | Limited | Wide |

| Setup time | High | Low |

| Drying time | Slow | Instant |

| Eco impact | Medium | Lower |

The comparison between screen printing vs UV printing is not about choosing one method over the other. Each method serves a different purpose. Screen printing is best for bulk and fabric-based printing, while UV printing works well for detailed designs and a wide range of materials. By understanding your project needs, you can easily choose the right printing method.

Screen printing is a good choice when your project involves large quantities of the same design. Once the screens are set up, printing many items becomes faster and more cost-effective.

This method works best when the design is simple, such as logos, text, or basic shapes. Since the ink is pushed deep into the material, screen printing is especially suitable for fabric items like t-shirts, bags, and uniforms.

It is also ideal when you need long-lasting prints. Screen-printed designs can handle regular washing and daily use, making them perfect for apparel and promotional merchandise.

Screen printing is best when:

UV printing is the right option when your design needs fine details and sharp clarity. It handles complex designs, gradients, and images very well, making it suitable for premium branding.

This method is also great when you need quick delivery. Since the ink dries instantly under UV light, there is no waiting time, and the printed item is ready to use immediately.

UV printing works perfectly on hard and non-fabric surfaces such as plastic, glass, metal, wood, and acrylic. It is also ideal for small or custom orders, as there is no screen setup involved.

UV printing is best when:

At Quapri, we do more than just print — we help turn your ideas into real, high-quality products. Whether you’re working with fabric, vinyl, wood, metal, or plastic, our team guides you toward the right printing method for your needs. From classic screen printing to modern UV digital printing, we make sure your product looks its best.

We handle everything from custom-printed merchandise and labels to corporate gifts, bulk apparel, packaging and event promotions. No matter the size of your order, we focus on quality, clarity, and consistency.

Clients choose Quapri because we offer:

Custom printing doesn’t have to be complicated. At Quapri, we keep it simple, reliable, and stress-free. Whether you need expert advice, a quick quote, or a complete printing solution, our team is always ready to help.

👉 Check out our catalogue to explore our full product range and get started today.

Available in custom shapes to suit your unique design needs.

Printed with high-quality materials for long-lasting durability.

Ideal for apparel branding, team uniforms, and custom garment designs.

Minimum order quantity 25

Features a vibrant rainbow effect with a smooth glossy finish.

Perfect for branding, labels, packaging, and promotional use.

Customizable with your logo, name, or artwork in any shape or size.

Need custom shapes or sizes? Tap the WhatsApp icon.

High-quality clear plastic stickers with a premium finish.

Any shape can be printed—simply upload your design and select your preferred size.

Stickers are supplied in sheets for easy handling and application.

No account yet?

Create an AccountUploaded Failed |  |