-

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

-

Personalized Coffee Mugs

₹235.00

Personalized Coffee Mugs

₹235.00

-

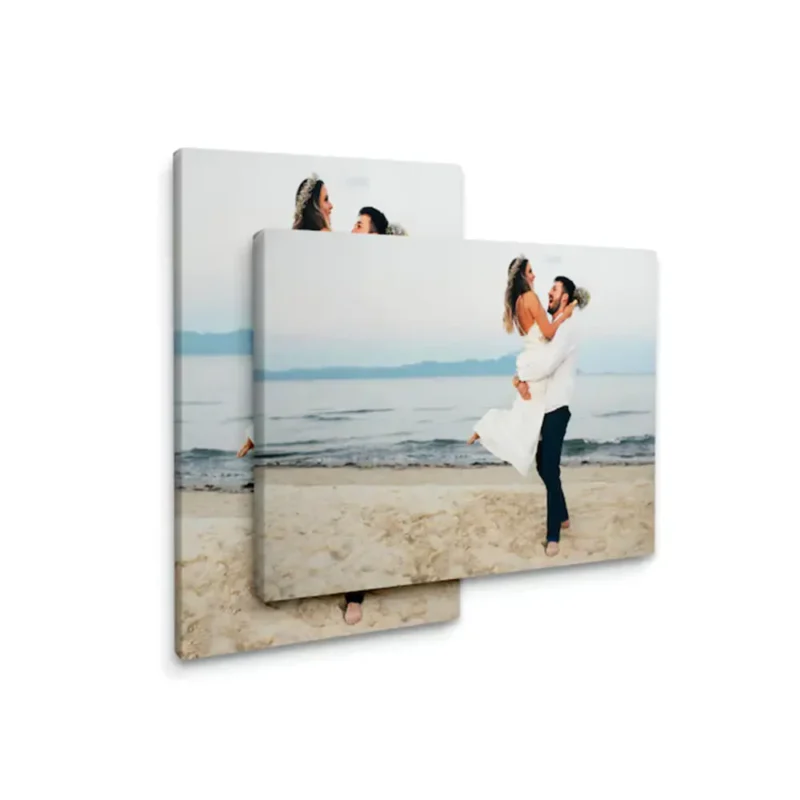

Custom Canvas Prints

₹715.00

Custom Canvas Prints

₹715.00

-

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Coffee Mugs

₹235.00

Personalized Coffee Mugs

₹235.00

Custom Canvas Prints

₹715.00

Custom Canvas Prints

₹715.00

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

Stainless Steel Bottles

₹450.00

Stainless Steel Bottles

₹450.00

5-in-1 Gift Set

₹2,500.00

5-in-1 Gift Set

₹2,500.00

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Eco-Friendly Business Card

From ₹4.60 per unit

Eco-Friendly Business Card

From ₹4.60 per unit

Circle Visiting Cards

From ₹2.25 per unit

Circle Visiting Cards

From ₹2.25 per unit

Metallic Business Cards

From ₹5.80 per unit

Metallic Business Cards

From ₹5.80 per unit

Matte Laminated Business Cards

From ₹3.20 per unit

Matte Laminated Business Cards

From ₹3.20 per unit

Glossy Laminated Visiting Cards

From ₹2.35 per unit

Glossy Laminated Visiting Cards

From ₹2.35 per unit

Personalized Bamboo Pencils

From ₹45.00 per unit

Personalized Bamboo Pencils

From ₹45.00 per unit

Premium Black Ballpoint Pen

₹410.00

Premium Black Ballpoint Pen

₹410.00

Metallic Ballpoint Pens

₹180.00

Metallic Ballpoint Pens

₹180.00

Stainless Steel Bottles

₹450.00

Stainless Steel Bottles

₹450.00

Temperature Water Bottles

₹900.00

Temperature Water Bottles

₹900.00

Personalized Bamboo Water Bottles

₹1,150.00

Personalized Bamboo Water Bottles

₹1,150.00

Thermos Water Bottles

Thermos Water Bottles

Awards and Certificates

Awards and Certificates Lanyards

From ₹25.20 per unit

Lanyards

From ₹25.20 per unit

Lanyard with Side Lever Hook

From ₹48.00 per unit

Lanyard with Side Lever Hook

From ₹48.00 per unit

Lanyard with Twisted Hook

From ₹46.25 per unit

Lanyard with Twisted Hook

From ₹46.25 per unit

Understanding the various types of t-shirt printing techniques is key to selecting the best quality custom apparel. From the timeless screen printing to cutting-edge digital printing, heat transfer, and direct-to-garment (DTG) methods, there are many techniques available to bring designs to life. These options enable individuals and businesses to make informed decisions based on their specific needs and creative vision.

Screen printing is one of the oldest and most reliable methods for T-shirt printing. It creates a stencil for each color in the design, then uses these stencils to apply layers of ink onto the fabric. While it requires setup time for large orders, it’s effective for bulk printing, especially when vibrant colors and durability are important.

Cost-effective for Bulk Orders: This method is affordable for large quantities, with the cost per unit dropping as you print more. Bulk t-shirt printing at a lower price point is ideal for businesses and events.

Durability: The ink is absorbed into the fabric, making the print long-lasting and resistant to fading. Durable T-shirt prints that stay vibrant over time.

Vibrant Colors: Screen printing produces bold, opaque colors that stand out on various fabrics. Vibrant T-shirt colors make your designs pop.

Direct-to-Garment (DTG) printing uses a specialized printer to print designs directly onto fabric, similar to inkjet printing. This method is perfect for detailed designs, photos, and small print runs, offering high-quality, full-color prints with no need for screens or stencils.

High Detail: DTG is ideal for intricate, multi-color designs or photos, delivering precision. High-quality digital prints bring out fine details and vibrant colors.

Soft Finish: The ink bonds with the fabric, offering a soft, breathable print without any raised texture. Soft-touch custom prints are comfortable and wearable.

Handles Complex Designs: DTG can manage gradients and fine details with ease, making it great for complex artwork. Complex design printing is made easy with DTG technology.

Heat transfer printing uses heat and pressure to transfer designs from transfer paper or vinyl sheets onto fabric. It’s a versatile method, ideal for small orders, and offers flexibility in the types of designs you can create.

Quick Turnaround: Heat transfer printing is fast, making it great for custom tees when you’re short on time. Fast custom t-shirt printing is ideal for quick promotions or events.

Works on Multiple Fabrics: It can be used on various materials like cotton, polyester, and blends, offering versatility. Multifabric heat transfer ensures compatibility with a wide range of T-shirt materials.

Affordable for Small Orders: Since there are no setup costs, it’s budget-friendly for small batches. Affordable custom prints for personal orders or small businesses.

Vinyl cutting uses a plotter to cut designs from colored vinyl sheets, which are then heat-pressed onto fabric. This method is perfect for simple designs like logos, text, and minimal graphics, ensuring sharp, crisp lines.

Crisp, Clean Designs: Vinyl cutting creates sharp lines, making it ideal for logos, bold text, and simple graphics. Sharp vinyl T-shirt graphics ensure a polished look.

Durability: The vinyl is tough, ensuring that your design won’t crack, peel, or fade over time. Long-lasting vinyl prints won’t lose their quality after washing.

Variety of Finishes: Vinyl comes in matte, gloss, or metallic finishes, giving you flexibility in design. Custom vinyl finishes allow you to choose the perfect texture and effect for your design.

Sublimation printing uses heat to transfer dye into the fibers of the fabric, creating vibrant, full-color prints that won’t fade, crack, or peel. It works best on polyester fabrics or polymer-coated materials, making it perfect for all-over designs, sportswear, and performance apparel.

No Cracking or Peeling: The dye bonds with the fabric, ensuring the design won’t fade or crack. Durable sublimation prints won’t degrade over time.

Vivid, Long-lasting Colors: Sublimation produces bright, clear colors that stay sharp even after multiple washes. Long-lasting sublimation designs maintain their vibrancy.

Perfect for All-over Prints: Ideal for full-coverage designs, such as sports jerseys or unique patterns. Full coverage sublimation is ideal for all-over t-shirt designs.

Types of T-shirt printing, like vinyl cutting and heat transfer, provide more design flexibility depending on order requirements.

When choosing the right t-shirt printing method, there are a few things to think about, like the design, how many shirts you need, the fabric, and how long you want the print to last. If your design is complex with lots of colors, DTG or sublimation are great options. For bulk orders, screen printing is your go-to because it’s super cost-effective. If you're only printing a few shirts, heat transfer or vinyl cutting might be a better fit. Make sure to consider the fabric too—sublimation works best on polyester, while screen printing is more versatile. And for prints that last, screen printing and vinyl cutting are both durable options.

Order Quantity

Screen printing is perfect for large orders because it’s cost-effective—the price per unit decreases with higher quantities. For smaller orders or unique one-off prints, DTG printing works best.

Fabric Type

DTG and screen printing are ideal for cotton and cotton blends, delivering vibrant, durable prints. For polyester or synthetic materials, sublimation printing provides excellent results.

Design Complexity

If your design includes fine details, multiple colors, or photorealistic imagery, DTG and sublimation are more accurate. Vinyl and heat transfer are better for simpler designs.

Durability Requirements

For prints that last through repeated washings and wear, screen printing and sublimation are great options, especially for premium clothing.

Budget

Screen printing offers a lower cost per unit for large orders, while heat transfer printing is more budget-friendly for small runs or DIY projects.

| Purposes | Best Method |

|---|---|

| Bulk Orders | Screen Printing |

| Single Custom Orders | DTG |

| Full-Color Prints | Sublimation |

| Athletic Wear | Vinyl Cutting |

| Home DIY Projects | Heat Transfer |

At Quapri, we’re dedicated to delivering top-quality custom t-shirt printing that brings your designs to life. Whether you're creating shirts for a business, event, or personal use, we ensure that every order meets the highest standards. Here’s why you should choose us for your t-shirt printing needs:

Take your creative ideas and turn them into standout designs with Quapri! Whether you need custom t-shirts for business branding, personal expression, or special events, we offer a variety of premium printing options that ensure your designs come to life with vibrant colors and lasting quality. Our quick turnaround times, eco-friendly materials, and affordable pricing make Quapri your go-to choice for all things custom t-shirt printing. Don’t settle for less—create something extraordinary today!

Start designing your custom t-shirts with Quapri now and let your creativity shine!

No account yet?

Create an AccountUploaded Failed |  |