-

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

-

Personalized Coffee Mugs

₹235.00

Personalized Coffee Mugs

₹235.00

-

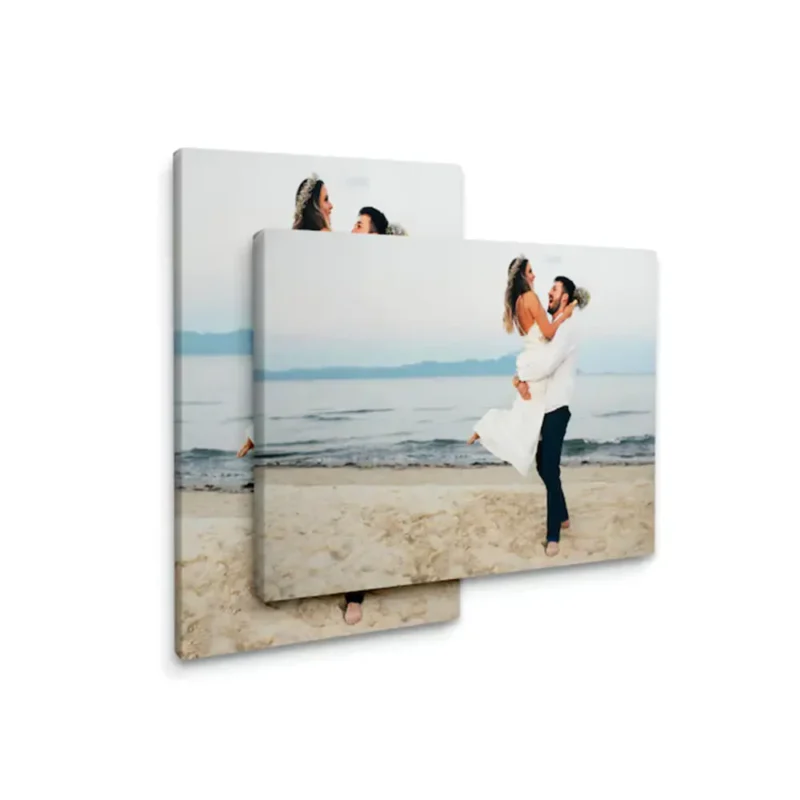

Custom Canvas Prints

₹715.00

Custom Canvas Prints

₹715.00

-

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Coffee Mugs

₹235.00

Personalized Coffee Mugs

₹235.00

Custom Canvas Prints

₹715.00

Custom Canvas Prints

₹715.00

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Personalized Notebooks

From ₹225.00 per unit

Personalized Notebooks

From ₹225.00 per unit

Stainless Steel Bottles

₹450.00

Stainless Steel Bottles

₹450.00

5-in-1 Gift Set

₹2,500.00

5-in-1 Gift Set

₹2,500.00

Premium Laminated Cards

From ₹3.30 per unit

Premium Laminated Cards

From ₹3.30 per unit

Eco-Friendly Business Card

From ₹4.60 per unit

Eco-Friendly Business Card

From ₹4.60 per unit

Circle Visiting Cards

From ₹2.25 per unit

Circle Visiting Cards

From ₹2.25 per unit

Metallic Business Cards

From ₹5.80 per unit

Metallic Business Cards

From ₹5.80 per unit

Matte Laminated Business Cards

From ₹3.20 per unit

Matte Laminated Business Cards

From ₹3.20 per unit

Glossy Laminated Visiting Cards

From ₹2.35 per unit

Glossy Laminated Visiting Cards

From ₹2.35 per unit

Personalized Bamboo Pencils

From ₹45.00 per unit

Personalized Bamboo Pencils

From ₹45.00 per unit

Premium Black Ballpoint Pen

₹410.00

Premium Black Ballpoint Pen

₹410.00

Metallic Ballpoint Pens

₹180.00

Metallic Ballpoint Pens

₹180.00

Stainless Steel Bottles

₹450.00

Stainless Steel Bottles

₹450.00

Temperature Water Bottles

₹900.00

Temperature Water Bottles

₹900.00

Personalized Bamboo Water Bottles

₹1,150.00

Personalized Bamboo Water Bottles

₹1,150.00

Thermos Water Bottles

Thermos Water Bottles

Awards and Certificates

Awards and Certificates Lanyards

From ₹25.20 per unit

Lanyards

From ₹25.20 per unit

Lanyard with Side Lever Hook

From ₹48.00 per unit

Lanyard with Side Lever Hook

From ₹48.00 per unit

Lanyard with Twisted Hook

From ₹46.25 per unit

Lanyard with Twisted Hook

From ₹46.25 per unit

T-shirts are more than everyday wear—they’re powerful tools for branding, personal style, and marketing. The right printing methods for T-shirts decide the quality, durability, and overall look of your design. Whether you need custom T-shirts for events, custom made shirts for your business, or are searching for T-shirt printing near me, knowing the options helps you make the best choice. Before you order custom T-shirts online, explore different techniques to find the one that matches your design, budget, and long-term use.

Not all T-shirt printing methods give the same results. The method you choose affects how long the design lasts, how it feels on the fabric, and how bright the colors stay after many washes. When buying custom tee shirts, the right method can mean the difference between a long-lasting shirt and one that fades or cracks quickly. For businesses using custom T-shirt printing or print on demand shirts, the right choice ensures better quality, happy customers, and more repeat orders.

Screen printing is one of the oldest and most reliable T-shirt printing methods. It uses stencils (screens) to press ink onto fabric, producing bold, vibrant designs. This method is durable and cost-effective for bulk orders, which is why it’s popular for custom T-shirts at events, promotions, and giveaways. The main drawback is the setup cost, making it less suitable for small batches or designs that require smooth gradients. Screen printing remains a top choice for branded apparel in large quantities.

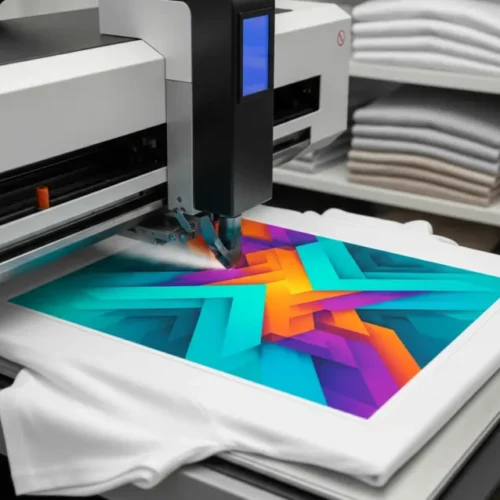

DTG printing works like an advanced inkjet printer, spraying ink directly onto fabric. This allows for detailed, full-color personalized T-shirt designs with smooth shading. Since there are no setup costs, it’s ideal for small orders and print on demand shirts. It is especially suited for artistic designs that need precision. However, DTG is slower for large-scale production and performs best on cotton fabrics, which makes it less practical for bulk custom tees.

Heat transfer Printing Methods for T-Shirts uses heat and pressure to apply a design onto fabric. This method is popular for custom T-shirts online because it supports detailed graphics and colorful designs. It’s affordable for small runs and flexible for trendy custom tees or startup brands. The drawback is durability—over time, the print may peel or fade with repeated washing. Heat transfer is ideal for short-term promotional wear, fashion pieces, or personalized T-shirts that need quick turnaround.

Sublimation is a process where ink turns into gas and bonds with polyester fibers. This creates vibrant, long-lasting prints that won’t crack, peel, or fade. Sublimation is perfect for all-over designs, photo-quality images, and premium custom made shirts. The limitation is that it works only on polyester or light-colored fabrics, making it unsuitable for cotton or dark tees. For brands that want bold graphics on performance wear or promotional apparel, sublimation delivers excellent results.

Vinyl printing involves cutting shapes or text from vinyl sheets and pressing them onto fabric with heat. It produces solid, eye-catching colors, making it a great choice for sports jerseys, names, and logos. Vinyl is durable and adds a bold finish, but it’s not suited for complex or large-scale designs. This method is best for simple custom T-shirt printing, team uniforms, and branded apparel that needs a sharp, professional look.

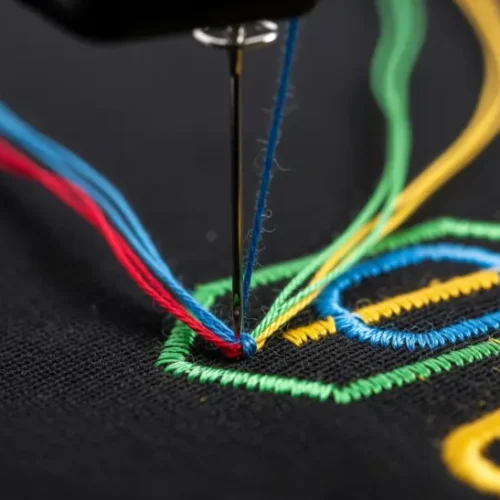

Embroidery uses stitched threads instead of ink to create designs on fabric. While it isn’t printing, it gives a premium, polished look to custom shirts. Embroidery is highly durable and ideal for business uniforms, corporate branding, and high-end personalized T-shirts. The limitation is that it’s more costly and cannot capture very fine details. However, for brands seeking a sophisticated and professional finish, embroidery remains a standout option. This is One of Printing Methods for T-Shirts

Picking the right T-shirt printing method doesn’t have to be confusing. It mostly depends on a few simple factors that can affect your custom tees or personalized T-shirts.

The world of custom tee shirts is evolving quickly, and keeping up with trends can help your designs stand out.

Start with a Design: Every custom t-shirt design begins with an idea—be it a logo, slogan, or graphic. Designers use tools like Photoshop or Illustrator to adjust size, colors, and placement so your personalized t-shirts look perfect.

Pick the Printing Method: Choosing the right Printing Methods for T-Shirts technique ensures quality and durability. Popular methods include screen printing (ideal for bulk orders), DTG printing (best for detailed custom tee shirts), heat transfer/vinyl (great for names or numbers), sublimation printing (for polyester fabrics), and embroidery (premium stitched finish).

Prepare the Fabric: Blank T-shirts are selected based on fabric type—cotton, polyester, or blends. DTG works best on cotton, sublimation suits polyester, while heat transfer is versatile for promotional t-shirts.

Print the Design: Depending on the method, ink is pressed, sprayed, bonded, or infused into the fabric. This step ensures vibrant, fade-resistant results for both single orders and bulk custom t-shirt printing near me.

Curing & Finishing: Shirts are heat-cured to lock in colors, making your custom printed t-shirts durable and washable.

Ready to Wear: Finally, T-shirts are checked, folded, and packaged. Businesses can add branded packaging, stickers, or custom tags to make promotional t-shirts more professional.

Quapri makes custom t-shirt printing easy, creative, and reliable. We offer high-quality options like screen printing, direct-to-garment (DTG), sublimation, and heat transfer, ensuring your design fits your style perfectly. Whether you need personalized t-shirts for events, promotional tees for branding, or bulk orders for your team, Quapri delivers with care. Using eco-friendly inks, durable fabrics, and advanced printing methods, we guarantee vibrant colors, long-lasting prints, and fast delivery.

👉 Bring your ideas to life—contact Quapri today and create t-shirts that truly stand out!

Explore more designs and options at QuapriCatalogue.com

No account yet?

Create an AccountUploaded Failed |  |